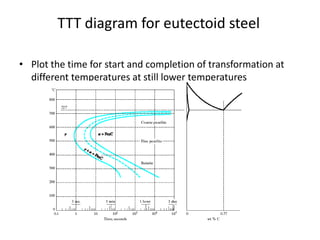

43 ttt diagram for eutectoid steel

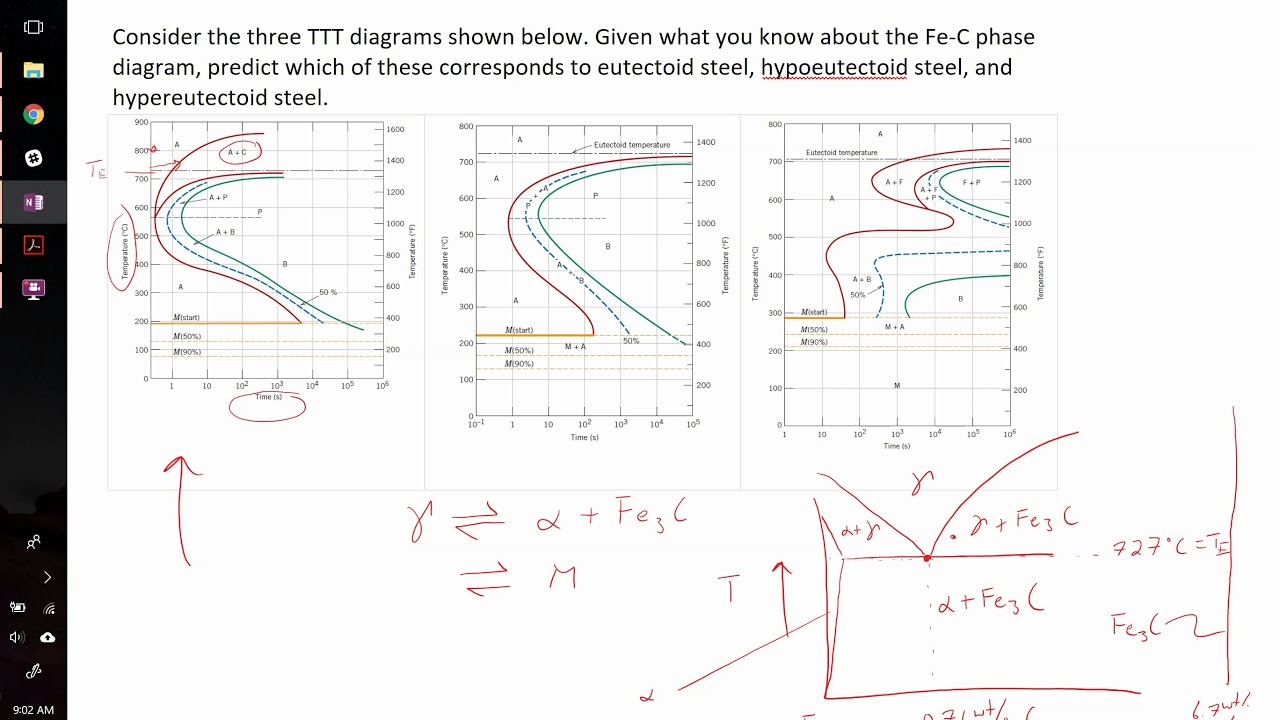

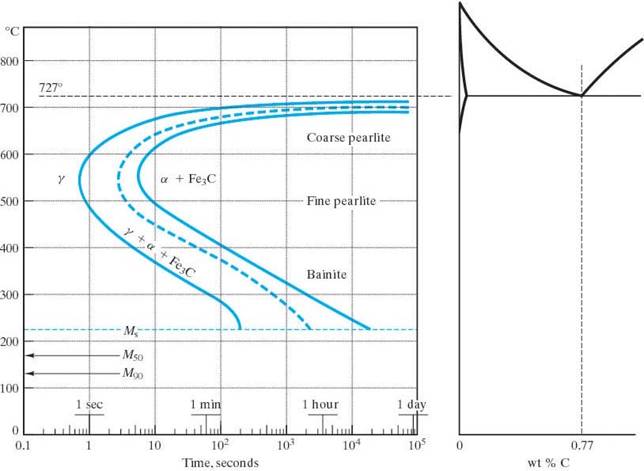

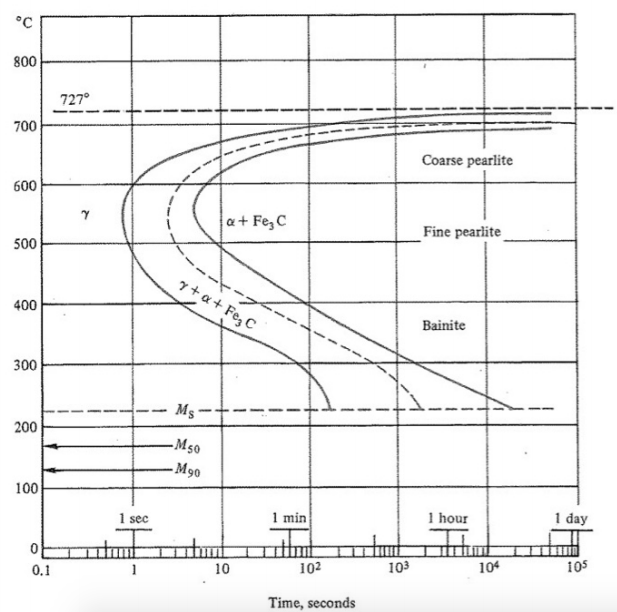

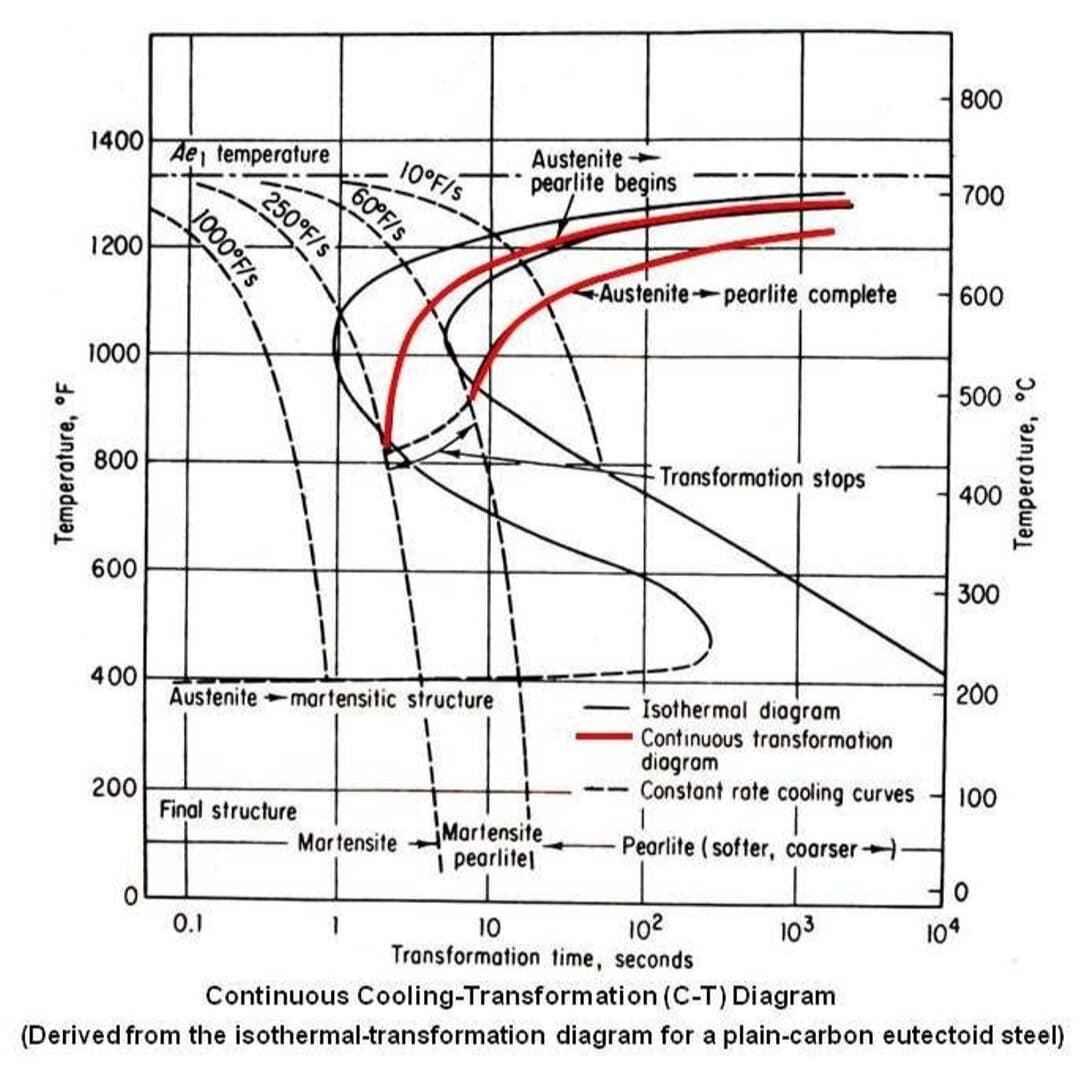

PDF Time-temperature- Transformation Diagram TTT Diagram On the other hand, TTT diagram is a more practical diagram. It shows what structures can be expected after various rates of cooling. It graphically describes the cooling rate required for the transformation of austenite to pearlite, bainite or martensite. TTT diagram also gives the temperature at Solved The TTT diagram for a 1077 eutectoid steel is given ... The TTT diagram for a 1077 eutectoid steel is given explain each heat treatment process: a) To form 50% Coarse Bainite -50% Martensite. b) To form 50% Coarse Pearlite -50% Fine Bainite. Temperature C) Temperature 20- 1 1 10 102 103 104

TTT diagram of eutectoid steel and martensitic transformation TTT diagram of eutectoid steel and martensitic transformation 1. Muhammad Umair Bukhari Engr.umair.bukhari@gmail.com 2.

Ttt diagram for eutectoid steel

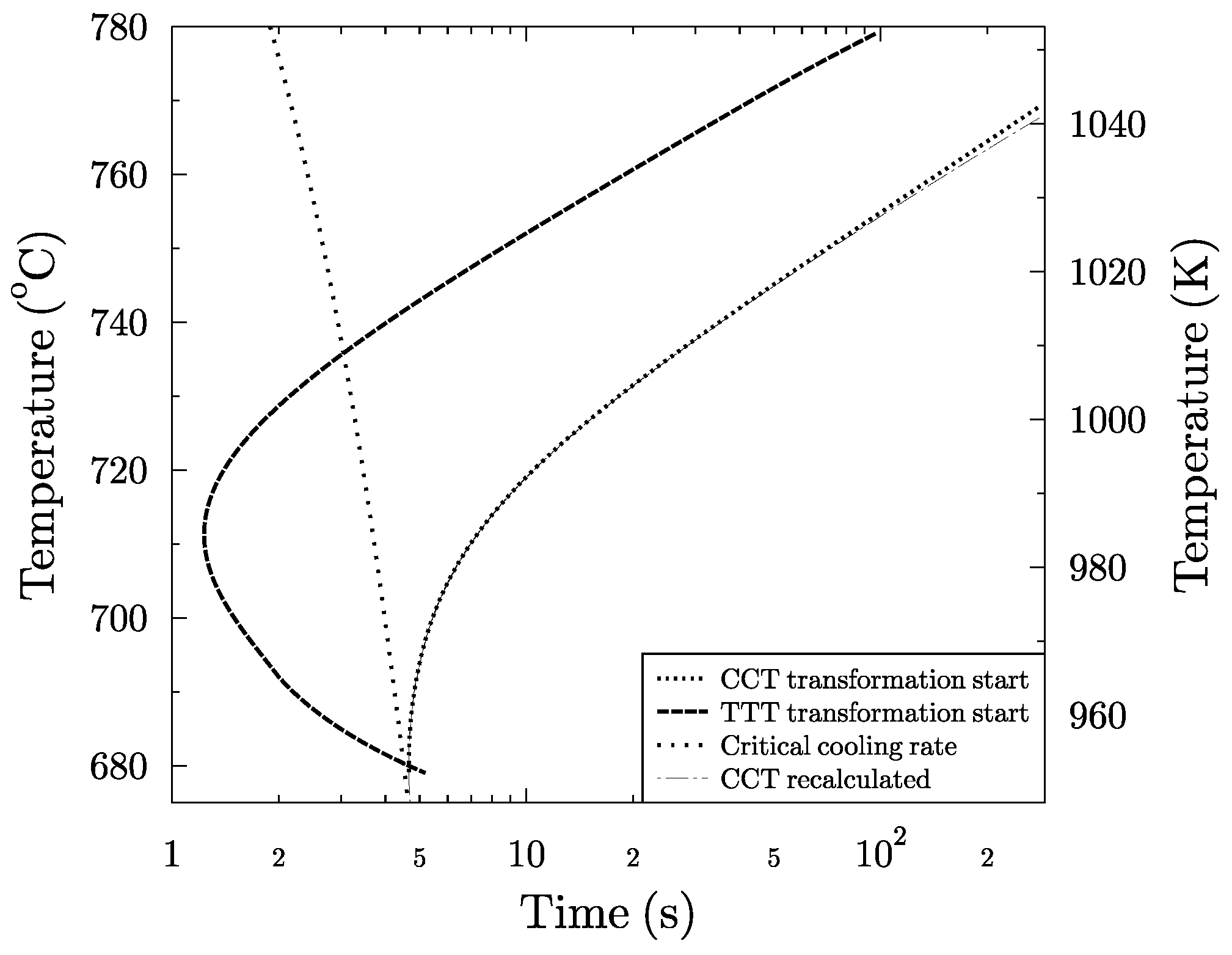

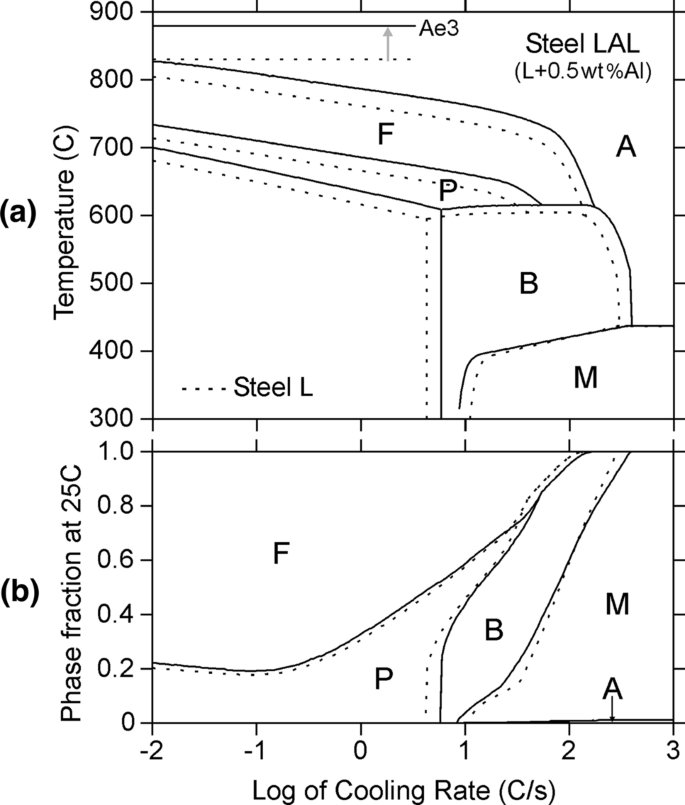

TTT Diagram Basic - TTT diagram for steel, eutectoid steel Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels. This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain's curve. The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram. These diagrams are extensively used in the assessment of the decomposition of austenite in heat-treatable steels. Nimertis_Salonitis(a).pdf - Nemertes από Κ Σαλωνίτης · 2006 — 2 Continuous-Cooling Temperature (CCT) diagram – διάγραµµα συνεχούς ψύξης ... laser beams – I. Hypo-eutectoid steels”, Acta Metallurgica, Vol. 32, No.252 σελίδες 2.25 Isothermal Transformation (IT) Diagrams for a ... 2.20 Heat Treating a Plain Carbon Eutectoid Steel 2:49. 2.21 Formation of Pearlite in Eutectoid Steel ... 2.24 Heat Treatments of Austenite Decomposition Products 2:11. 2.25 Isothermal Transformation (IT) Diagrams for a Eutectoid Steel 6:31. 2.26 Off-Eutectoid Isothermal Transformation (IT) Diagrams 7:18. 2.27 4340 Isothermal Transformation (IT ...

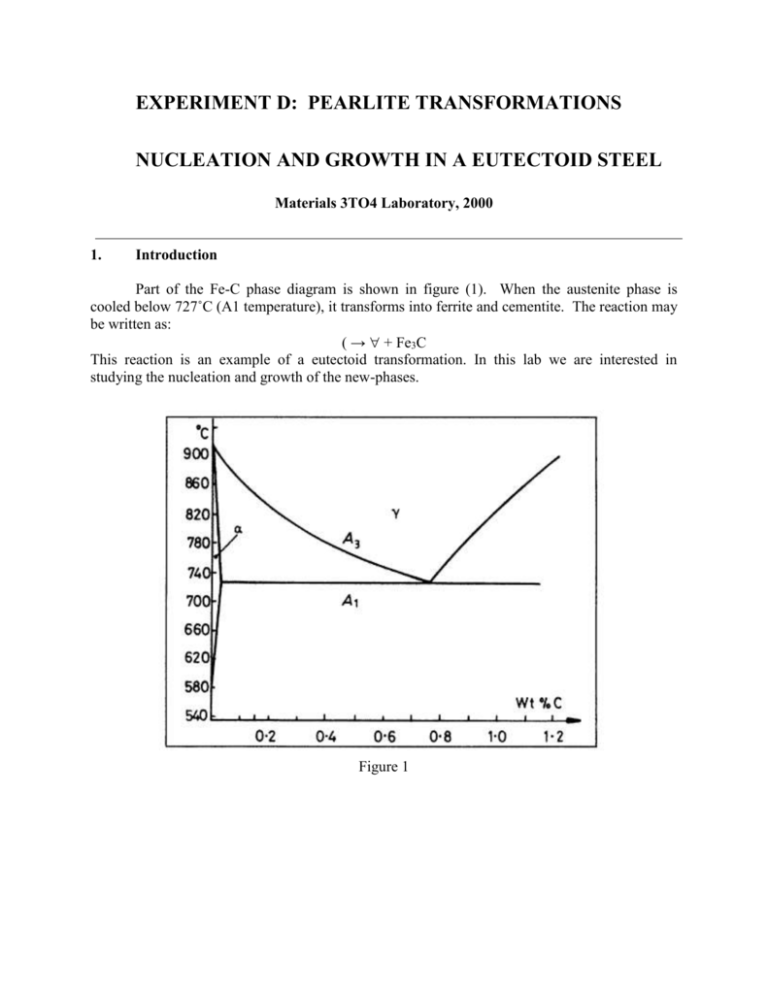

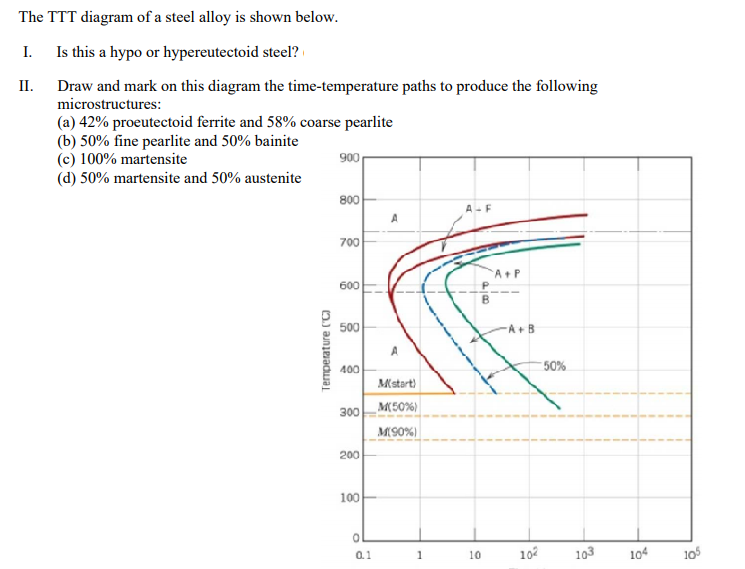

Ttt diagram for eutectoid steel. PDF Lecture 19: Eutectoid Transformation in Steels: a typical ... the iron-carbon alloy system. A sample of the eutectoid composition is cooled from a single-phase region (γ) to a temperature (T) below the eutectoid temperature (T E). The following diagram shows a part of the iron-carbon phase diagram. Concentrations C 1, C 2, C 3, C 4 are various equilibrium ( stable as well as metastable ) concentrations ... ttt diagram for hypo and hyper eutectoid steel TTT diagrams for eutectoid steel (0.8% C), hypoeutectoid (< 0.8% C) and hypereutectoid (> 0.8% C) steels are shown below. Pearlite (P) and bainite (B) form by distinct processes, with their own Ccurves. To an adequate approximation, pearlite forms above the "knee", and bainite below. For hypoeutectoid steels, some ferrite (F) PDF Time Temperature Transformation (TTT) Diagrams Determination of TTT diagram for eutectoid steel Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified and included M S and M F temperatures for martensite. There are number of methods used to determine TTT diagrams. These are salt bath (Figs. 1- 4140 Steel Ttt Diagram TTT diagram stands for "time-temperature-transformation" diagram . It is Determination of TTT diagram for eutectoid steel. Davenport and TTT diagram for. US steel: (a) US , (b) US , (c) US and (d) US was compared with the published TTT diagram for a given chemistry and y grain size for an AISI steel. The calculated response was subsequently tested.

Ttt Diagram For Hypoeutectoid Steel Ttt Diagram Of Eutectoid Steel 21 Time Temp Curve Showing The . Welding Ttt Diagram Wiring Diagram Data . Ttt Diagram . Heat treating or heat treatment is a group of industrial and metalworking processes used to alter the physical and sometimes chemical properties of a material. Ttt diagram for hypoeutectoid steel. Its extremely important to ... TTT Diagram of steel in Material science - Materials Today Presented above is the TTT-diagram for eutectoid steel. For each composition, there will be a slight variation in diagram curves. TTT diagram of steel indicates the time-temperature and transformation curve. This means transformation is dependent upon time, temperature, and cooling mechanism. Difference between phase diagram and TTT diagram of steel Ttt Diagram Of Aisi 1045 Steel - yvc.moeys.gov.kh Determination of ttt diagram for eutectoid steel. Ttt diagrams give the kinetics of isothermal transformations. The continuous cooling transformation (cct) diagram shown on figure 1, is a plot of temperature versus the logarithm of time for a steel . Each cooling curve shows the beginning and end of the decomposition of austenite to the final ... PDF Heat Treatment of Steels Fe3C at Eutectoid Transformation ... be different than a TTT diagram. 15 Slow Cooling Time in region indicates amount of microconstituent! 16 Medium Cooling Cooling Rate, R, is Change in Temp / Time °C/s. 17 Fast Cooling This steel is very hardenable… 100% Martensite in ~ 1 minute of cooling! 18

Ttt Diagram 1045 Steel - Wiring Diagrams A slow cooling path that leads to coarse pearlite formation is superimposed on the TTT diagram for eutectoid steel. AISI-SAE - % C be different than a TTT diagram. 15 Slow Cooling Time in region indicates amount of microconstituent! 16 Medium Cooling Cooling Rate, R, is Change in Temp / Time °C/s. 17 Fast Cooling This steel is very ... TTT diagram of Hypoeutectoid and Hypereutectoid steels ... TTT diagram of Hypoeutectoid and Hypereutectoid steels - YouTube. The TTT Diagram for Eutectoid Steel - Making Things Fast ... We'll examine the lead-tin phase diagram and look at its practical applications as an example of making something slowly. Then we'll evaluate the TTT diagram for eutectoid steel, and compare diffusional to diffusionless transformations with the TTT diagram, monitoring how we make things rapidly. Lesson ten is a brief history of semiconductors. Hypoeutectoid Steel - an overview | ScienceDirect Topics TTT diagrams for (a) eutectoid, (b) hypoeutectoid, and (c) hypereutectoid steels. (b) and (c) show (dashed lines) the C-curves for the formation of primary α and Fe 3 C, respectively. Note that as the carbon content increases, both M s and M F decrease.

TTT Diagram for Eutectoid Steel | TTT Phase diagram ... #modimechanicalengineeringtutorials, #mechanicalmagicmechanicallearningtutorials,Welcome to My YouTube Channel MODI MECHANICAL ENGINEERING TUTORIALS.This ch...

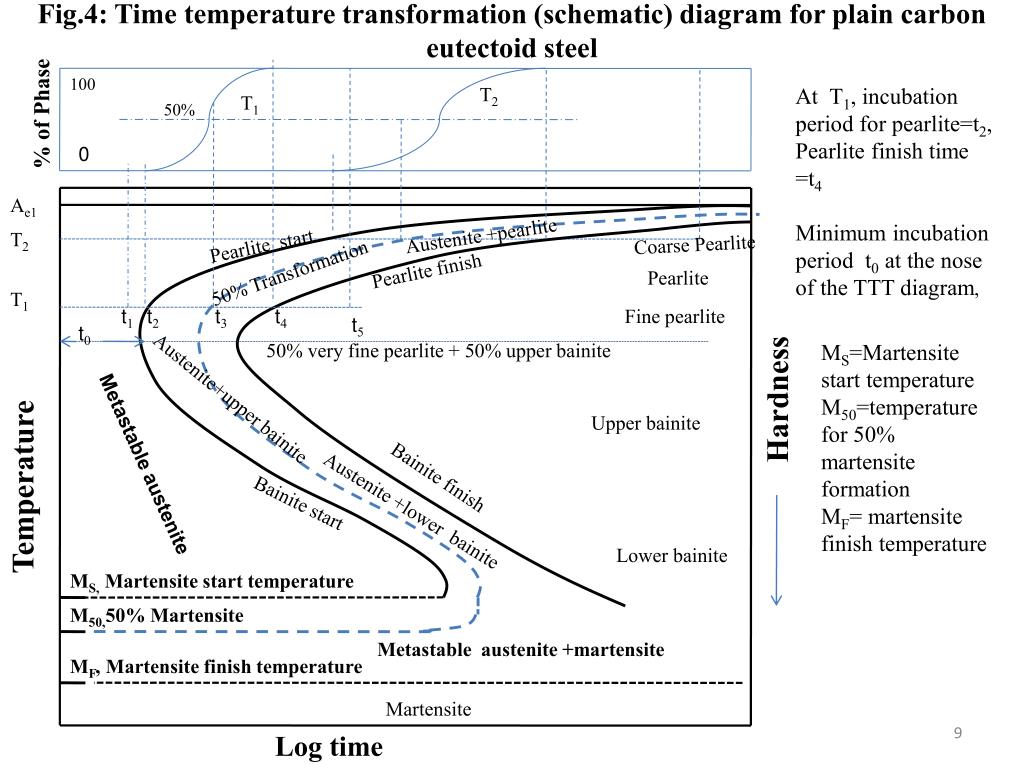

TTT Diagram - Metallurgy for Dummies TTT diagram indicates when a specific transformation starts and ends and it also shows what percentage of transformation of austenite at a particular temperature is achieved. Look at figure 1b and 1c. Figure 2. Upper half of TTT Diagram (Austenite-Pearlite Transformation Area) Figure 2 represents the upper half of the TTT diagram.

PDF Time-Temperature-Transformation (TTT) Curves ttt diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. ttt diagram indicates a specific transformation starts and ends and it also shows what percentage of transformation of austenite at a particular temperature is achieved. the aims of ttt diagrams is determined type of structure for and …

PDF T-t-t Diagram for Eutectoid Steel Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels. This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and ain's curve. The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram.

Ttt Diagram For Eutectoid Steel - schematron.org Determination of TTT diagram for eutectoid steel. Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and .TTT Diagram • The TTT digrams for hyper-eutectoid steels will differ from that of eutectoid steels • The TTT diagrams for hyper-eutectoid steels will have an additional curve to show the precipitation of cementite from martensite before transformation of remaining austenite to pearlite TTT diagram for a hypereutectoid Steel ( wt ...

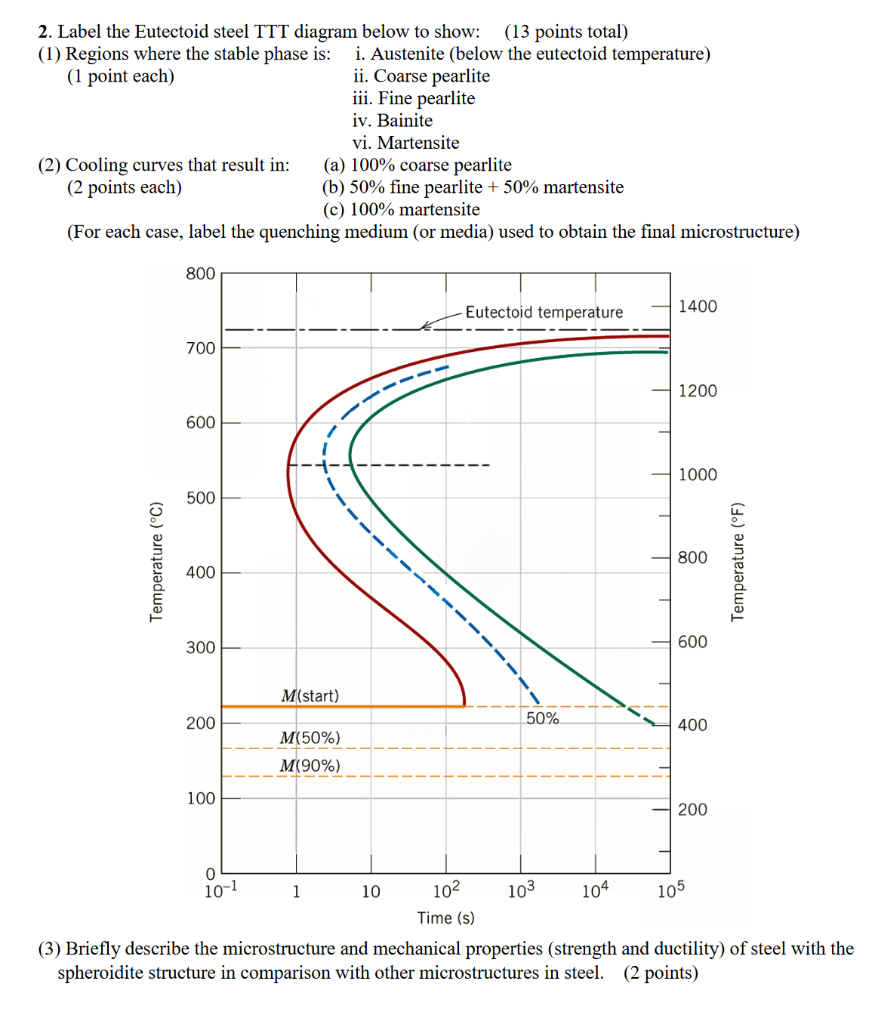

TTT Diagrams: Introduction and Limitations | Material ... As shown in complete TTT diagram for eutectoid steel in figure above approximately 550°C-600°C, austenite transforms completely to pearlite. Below this range up to 450°C, both pearlite and bainite are formed. Finally, between 450°C and 210°C, the reaction product is bainite only.

PDF TTT & CCT Diagram Part 2 Lect-6 - University of Technology ... Schematic T TT diagrams for eutectoid, hypoeutectoid and hyper eutectoid steel are shown in Fig.", Figs. 7(a)-(b) and all of them together along with schematic Fe-Fe3C metastable equilibrmm are shown in Fig. 8. ecm

TTT diagram - SlideShare TTT Diagram • The TTT digrams for hyper-eutectoid steels will differ from that of eutectoid steels • The TTT diagrams for hyper-eutectoid steels will have an additional curve to show the precipitation of cementite from martensite before transformation of remaining austenite to pearlite 53. TTT diagram for a hypereutectoid Steel (1.13 wt% C) 54.

Iron Carbon Ttt Diagram - schematron.org ttt diagram is a plot of temperature versus the logarithm of time for a steel alloy of the complete isothermal transformation diagram for an iron-carbon alloy.c metastable equilibrium diagram and ttt diagrams for plain carbon hypoeutectoid, eutectoid and hypereutectoid steels m s (a) fe-fe 3 c metastable phase diagram (b) ttt diagram for …

(PDF) Time Temperature Transformation (TTT) Diagrams ... Time Temperature Transformation (TTT) Diagrams R. Manna Assistant Professor Centre of Advanced Study Department of Metallurgical Engineering Institute of Technology, Banaras Hindu University Varanasi-221 005, India rmanna.met@itbhu.ac.in Tata Steel-TRAERF Faculty Fellowship Visiting Scholar Department of Materials Science and Metallurgy ...

Solved 1. Using the TTT diagram for Eutectoid Steel ... 1. Using the TTT diagram for Eutectoid Steel, specify the constituents and their approximate percentages of a small specimen subjected to the following time-temperature treatments. All begin with a completely Austenized specimen: - Rapidly cool to 650°C, hold for 100 seconds, then quench to room temperature.

TTT Diagrams and Heat Treatment of Steel | Metallurgy TTT diagram helps to fix the time and temperature of holding. The speed of motion of the wire through the bath should be such that it remains in bath for a time slightly greater than the time of completion of pearlitic transformation to avoid any chance of transformation of untransformed austenite to bainite, or martensite later.

2.25 Isothermal Transformation (IT) Diagrams for a ... 2.20 Heat Treating a Plain Carbon Eutectoid Steel 2:49. 2.21 Formation of Pearlite in Eutectoid Steel ... 2.24 Heat Treatments of Austenite Decomposition Products 2:11. 2.25 Isothermal Transformation (IT) Diagrams for a Eutectoid Steel 6:31. 2.26 Off-Eutectoid Isothermal Transformation (IT) Diagrams 7:18. 2.27 4340 Isothermal Transformation (IT ...

Nimertis_Salonitis(a).pdf - Nemertes από Κ Σαλωνίτης · 2006 — 2 Continuous-Cooling Temperature (CCT) diagram – διάγραµµα συνεχούς ψύξης ... laser beams – I. Hypo-eutectoid steels”, Acta Metallurgica, Vol. 32, No.252 σελίδες

TTT Diagram Basic - TTT diagram for steel, eutectoid steel Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels. This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain's curve. The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram. These diagrams are extensively used in the assessment of the decomposition of austenite in heat-treatable steels.

![TTT diagram of eutectoid steel [21] Time-temp curve showing ...](https://www.researchgate.net/profile/Tushar-Mamodia/publication/281651155/figure/fig3/AS:391435007348747@1470336786569/TTT-diagram-of-eutectoid-steel-21-Time-temp-curve-showing-the-formation-temp-Mf-of.png)

0 Response to "43 ttt diagram for eutectoid steel"

Post a Comment