45 petroleum refinery process flow diagram

Crude Oil Refinery Flow Diagram Showing Process Chemical Additives Financial benefits Whether it be extending equipment life due to corrosion inhibition, increasing production output due to enhanced deposit control, or shortening the the start-up time during sulphidation operations, we have resolved to provide you

The first step is the separation of crude oil to convert into various components by the process of distillation. The lighter constituent vaporizes or remains as ...1 answer · Top answer: In other words, petroleum refining processes convert the crude oil into useful products such as LPG, gasoline or petrol, asphalt base, heating oil, etc. ...

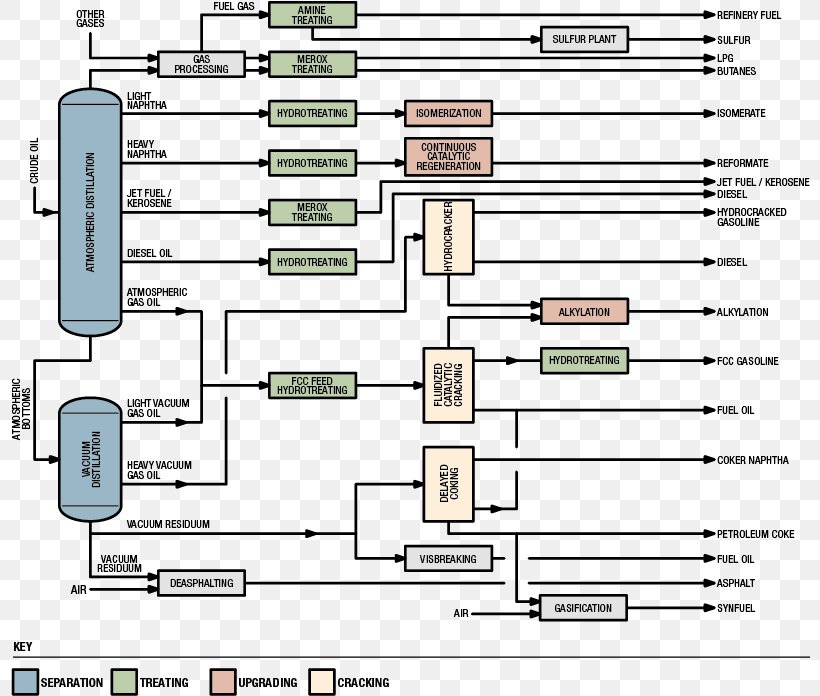

Flow diagram of a typical petroleum refinery. The image below is a schematic flow diagram of a typical petroleum refinery that depicts the various refining processes and the flow of intermediate product streams that occurs between the inlet crude oil feedstock and the final end-products.

Petroleum refinery process flow diagram

Simplified Flow Diagram of a Deasphalting Process. Figure 5.9 shows a simplified flow diagram of a propane deasphalting process. See a more detailed flow diagram in your textbook along with a description of the operating conditions in the commercial process.

4.2 Refinery flow sheet We now present a typical refinery flow sheet for the refining of middle eastern crude oil. There are about 22 units in the flow sheet which themselves are complex enough to be regarded as process flow sheets. Further, all streams are numbered to summarize

Petroleum Refinery Process Create Process Flow Diagram examples like this template called Petroleum Refinery Process that you can easily edit and customize in minutes. 2/16 EXAMPLES

Petroleum refinery process flow diagram.

Petroleum Refining Industry Study 5 August 1996 Table 3.7.5. Spent Dimersol Polymerization Catalyst Physical Properties..... 89 Table 3.7.6.

Petroleum Refinery Process Economics, 2nd ed. , by Robert E. Maples, PennWell Corp., 2000 75 blends 135 blends a 1 0.03224 0.03324 a 2 0.00101 0.00085 a 3 0 0 b 1 0.04450 0.04285 b 2 0.00081 0.00066 b 3-0.00645 -0.00632

This video was created for Penn State's F SC 432: Petroleum Processing course (https://www.e-education.psu.edu/egee101/) with the assistance of Semih Eser an...

topic discussed:Process flow diagram of refinery.---CHEMICAL ENGINEER Thank You for watching the video....Like, share and subscribe to the channel... Find us...

REFINERY— PROCESS FLOW DIAGRAMS 5 Process Flow Diagrams — Refinery Conversion Process — Typical Distillation Unit Process Desciptions One of the other feedstocks to a refinery is hydrogen, which can be used in a hydrotreater, isomerization, FCC, reformer, and a complex, capital-intensive unit.

Petroleum Refining Fourth Year Dr.Aysar T. Jarullah Alkylation Process Alkylation is the process of producing gasoline range material light olefins (primarily ... A block diagram of the process is shown in Figure below: Process Flow: Sulfuric Acid Alkylation In sulfuric acid (H 2 SO 4 ) alkylation units, the feeds - propylene, butylene ...

A Process Flow Diagram (PFD) is a diagram which shows the relationships between the main components in a system. Process Flow Diagrams are widely used by engineers in chemical and process engineering, they allows to indicate the general flow of plant process streams and equipment, helps to design the petroleum refineries, petrochemical and chemical plants, natural gas processing plants, and ...

Lecture 3: Petroleum Refining Overview In this lecture, we present a brief overview of the petroleum refining, a prominent process technology in process engineering. 3.1 Crude oil Crude oil is a multicomponent mixture consisting of more than 108 compounds. Petroleum refining refers to the separation as well as reactive

The petroleum refining industry employs a wide variety of processes. A refinery's processing flow scheme is largely determined by the composition of the crude oil feedstock and the chosen slate of petroleum products. The example refinery flow scheme presented in Figure 5.1-1 shows the general

Caustic treating is a refining process that uses an aqueous solution of NaOH to absorb acid gas compounds, like H 2S, CO 2, and mercaptans, found in natural gas or liquid hydrocarbon streams. Crude oil fractions that exit from the vapor stream in a distillation tower contain sulfur-based compounds, which are odiferous and corrosive.

This is a picture that we got from Bantrel.com showing the Crude oil refining process. Más información.

Download scientific diagram | Simplified flow chart of crude oil refinery processes. from publication: Biotechnology in the petroleum industry: An overview ...

[Oil refinery. Wikipedia] The PFD example "Process flow diagram - Typical oil refinery" was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Solution Park. Oil And Gas Production Process Flow Diagram

The image on the following page is a schematic flow diagram of a typical oil refinery that depicts the various unit processes and the flow of intermediate product streams that occurs between the inlet crude oil feedstock and the final end products. The diagram depicts only one of the literally hundreds of different oil refinery configurations.

How crude oil is refined into petroleum products. Petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocks for making chemicals.. Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products.

• Crude oil distillation is more complicated than product distillation, in part because crude oils contain water, salts, and suspended solids. • Step 1 in the refining process is to remove these contaminants so as to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning catalysts in processing units.

Edible oil refining process flow chart is usually designed by engineers according to customer's plant area and process requirements. Generally, edible oil refining process flow chart has three types based on the input capacity, batch type edible oil refining process flow chart, semi- continuous edible oil refining process flow chart and full-continuous edible oil refining process flow chart.

Flow diagram of typical refinery. The image below is a schematic flow diagram of a typical oil refinery that depicts the various unit processes and the flow of intermediate product streams that occurs between the inlet crude oil feedstock and the final end products. The diagram depicts only one of the literally hundreds of different oil ...

Crude Oil as Refinery Feedstock • Crude Oil Complex mixture of hydrocarbons & heterocompounds Dissolved gases to non‐volatiles (1000 F+ boiling material) C 1 to C 90 + • Composition surprisingly uniform 41 Element Wt% Carbon 84 ‐87 Hydrogen 11 ‐14 Sulfur 0 ‐5 Nitrogen 0 ‐0.2 Other elements 0 ‐0.1

The first step of this process is not demonstrated at the diagram, which is the heating of the crude oil to a temperature of 100-150 °C. The freshwater presents another inlet stream in this process, and its volume flow represents the 4-10% of the crude oil volume flow. The third stream is composed of the demulsifying agent.

fundamentals of petroleum refining, one must begin with crude oil. 3.1 The Chemical Constituents of Crude Oil Hundreds of different crude oils (usually identified by geographic origin) are processed, in greater or lesser volumes, in the world's refineries. Each crude oil is unique and is a complex mixture of thousands of compounds. Most of the

This is a classification of refining processes and the types of refinery products shown by a flow chart. The flow chart starts with crude oil. Above crude oil chemical constitution is written and below physical properties are written. Crude oil leads to the refining process including separation, conversion, finishing and support.

Figure 1: Refining Process Flow Diagram Introduction to Refining The modern crude oil refinery is designed to convert basic raw crude oil into various useful products through a series of separation and chemical processes. For example, the refinery process is used to produce gaso-line, kerosene, light oils, lubricating oils, and gases.

The Mini-Refineries are skid mounted, modular crude oil distillation units (CDU) which process from 50,000 to 450,000 metric tons (1000 - 9,000 BPD) of crude oil per year and are capable of producing a variety of finished products including naphtha (straight run gasoline), kerosene, arctic and summer diesel and fuel oil.

I'm working on a **4X game set in our solar system** only that focused on **asteroid mining and planetary colonies.** (More like 3X because no warfare yet, but eXtrapolate could easily added.) We've been spending the past several months incorporating data from the minor planet center and integrating general-purpose trajectory solving using the **ESA's astrodynamics** software. We have the software working, but still working out kinks on the ThreeJS coordinate system. We're trying to build the ...

10 Application Solutions Guide — Refinery Process GLOBAL REFINERY LANDSCAPE Figure 1.4: In-process refinery end products and finished marketable refinery end products diagram API for valves The oil and gas industry does not use a universal API specification for valves like they have on pumps and

Petroleum Refining is defined as the industrial process of production of useful petroleum products from crude oil. The plant where the useful products are separated from crude oil is known as a petroleum refinery. Crude oil or petroleum consists of various hydrocarbons. The crude oil refining process breaks the crude oil down into various components to make useful new products.

0 Response to "45 petroleum refinery process flow diagram"

Post a Comment