44 ttt diagram 1018 steel

BEFORE CONSIDERATION can be given to the heat treatment of steel ... 6 Time-temperature-transformation (TTT) diagram for a eutectoid (0.77%) carbon steel.18 pages Transformation TTT. Curves. Ttt Diagram 1018. Steel ulkucu de. Ttt. Diagram 1018 Steel PDF. Download haishahikitori com. Tue 28 Nov 2017 23.

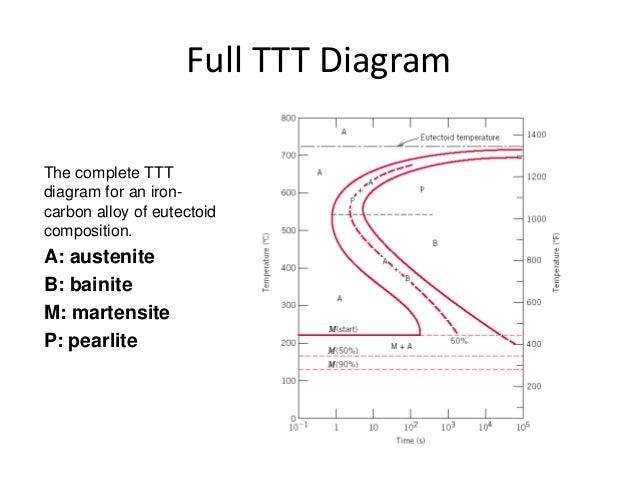

The effect of alloying on the shape of the TTT diagram is shown in Figure 8. Figure 7: Comparison of the effect of carbon on the TTT curves of plain carbon steel. Left is SAE 1020 steel. Right is SAE 1080 steel. Carbon pushes the nose (or knee) of the TTT curve to the right, retarding kinetics [3].

Ttt diagram 1018 steel

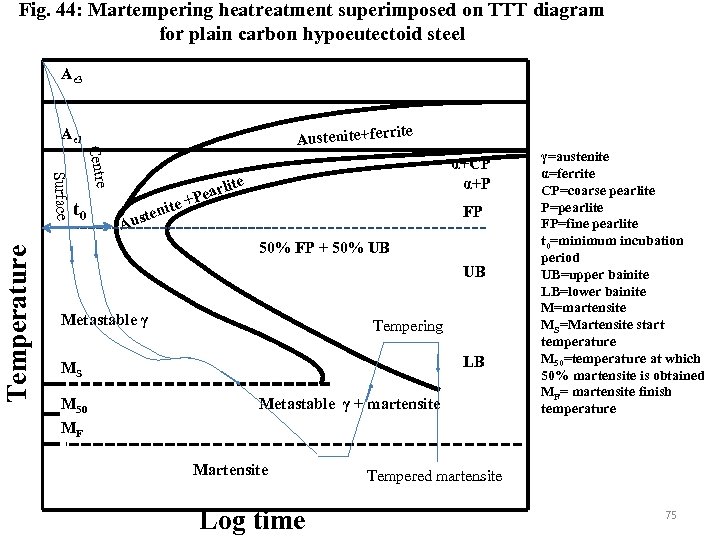

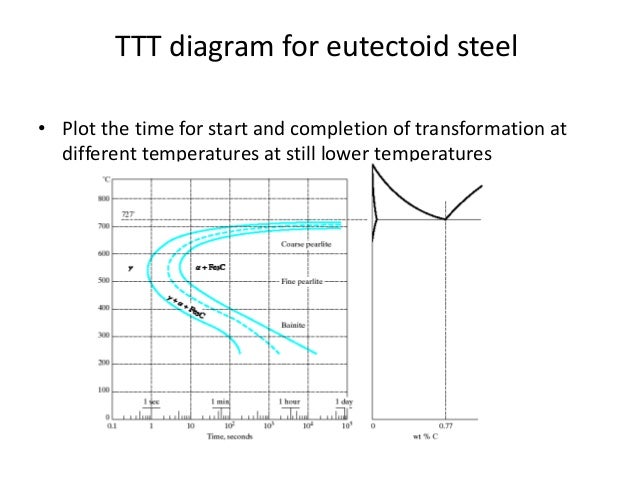

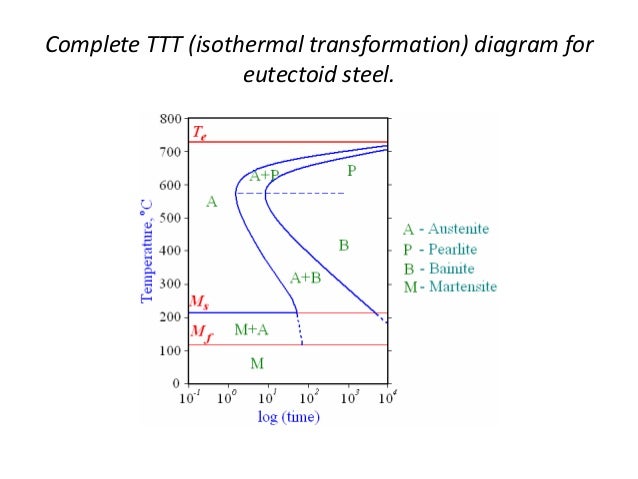

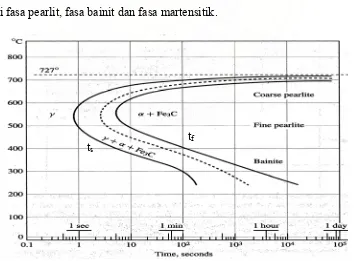

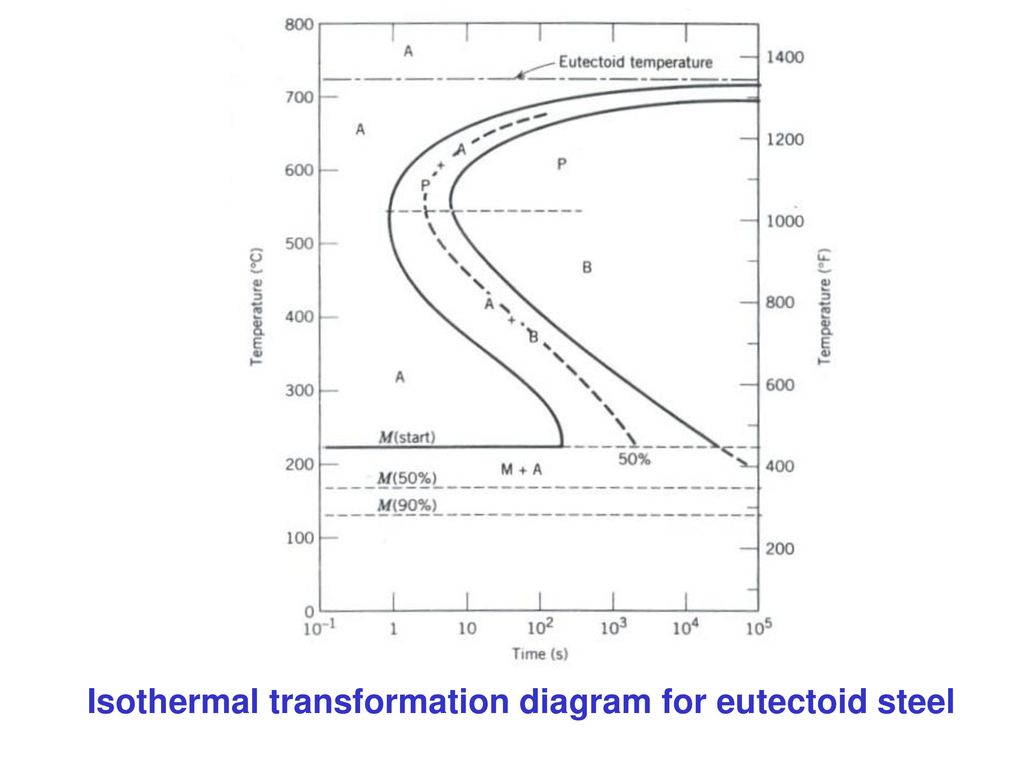

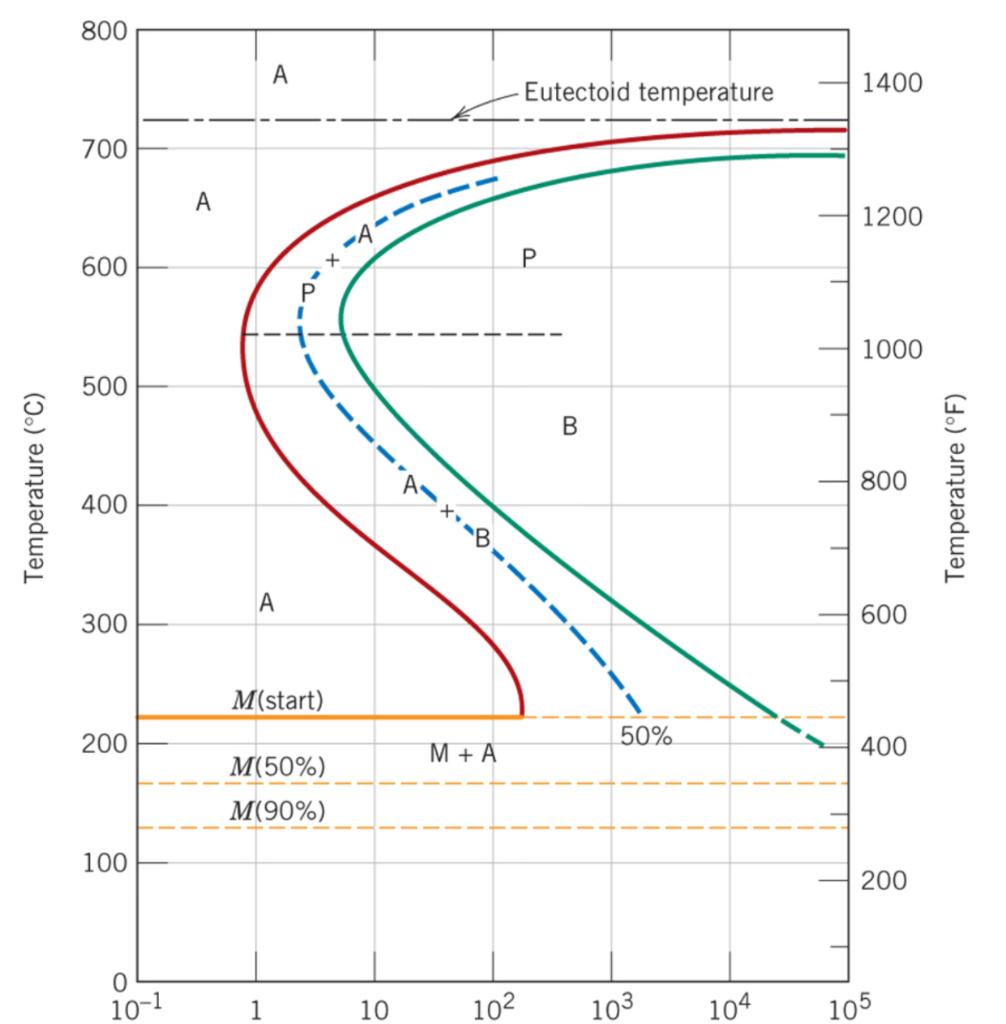

Determination of TTT diagram for eutectoid steel Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified and included M S and M F temperatures for martensite. There are number of methods used to determine TTT diagrams. These are salt bath (Figs. 1- Time-temperature isothermal transformation (TTT) diagram for AISI type 6150 carbon steel, austenitized at 850°C. Continuous cooling transformation (CCT) diagrams Measure the extent of transformation as a function of time for a continuously decreasing temperature. In other words a sample is austenitised and then cooled at a predetermined rate ... Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain’s curve.The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram.

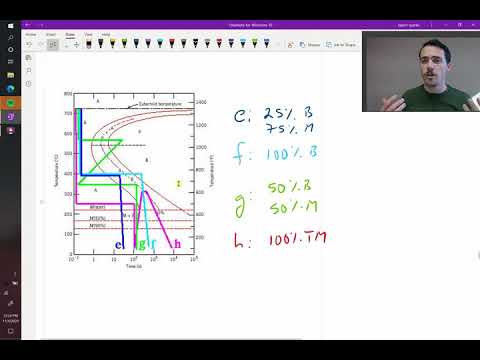

Ttt diagram 1018 steel. 3 Mar 2008 — Steel 1018 Steel 4340 Aluminum 2024 70-30 Brass ... TTT diagrams or hardness vs. time: For steel 1018: use 1019 graph attached to lab.27 pages Full TTT Diagram. The complete TTT diagram for an iron-carbon alloy of eutectoid composition. A: austenite. B: bainite. M: martensite. P: pearlite ...24 pages Treatment of Steels K Street Studio. Time Temperature Transformation TTT Diagrams. Free Ttt Diagram 1018 Steel PDF ePub Mobi. 1018 Chemical Composition, Mechanical Properties, Heat Treatment, 1018 Datasheets, 1018Supplier Author: Pan Bao - solew@qq.com Subject: 1018 Datasheets Keywords: 1018 Chemical composition, 1018 mechanical properties, heat treatment, 1018 Datasheets, 1018 Supplier TCPDF Created Date: 11/14/2021 11:22:45 AM

Figure 3.a shows a typical TTT diagram for plain carbon steel. The addition of carbon and alloying elements effect several parameters in TTT diagrams, such as the shape, martensite start temperature and relative position of the curve. In Figure 3.b, the effect of a small amount of Cr is seen. The TTT curve is shifted to right. by R Manna · Cited by 9 — Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified ...108 pages TTT diagram of hypoeutectoid and hypereutectoid steels AISI-SAE 1018 – 0.18 % C ... be different than a TTT diagram. 15 Slow Cooling Time in region indicates amount of microconstituent! 16 Medium Cooling Cooling Rate, R, is Change in Temp / Time °C/s. 17 Fast Cooling This steel is very hardenable… 100% Martensite in ~ 1

Read the effect of alloying elements on TTT curve in any physical metallurgy book or ASM handbook. This will provide you an insight on the transformation curve and products. I have not failed. I've just found 10,000 ways that won't work." — Thomas Edison. RE: Compare the TTT diagram of 1018 and 4340. The TTT diagram of steel is considered an important transformation diagram for non-equilibrium transformation.There are various non-equilibrium products like Martensite, Bainite which can not be formed by continuous cooling and so can not be explained with phase transformation diagram explained in Martensitic transformation post and Widmanstatten transformation post. 1020 STEEL TTT DIAGRAM ROUNDSTEELBAR. TTT DIAGRAM 1018 STEEL SWHEFT. DE. FREE TTT DIAGRAM 1018 STEEL PDF EPUB MOBI. WHAT IS THE. DIFFERENCE BETWEEN CCT AND ... Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain’s curve.The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram.

Time-temperature isothermal transformation (TTT) diagram for AISI type 6150 carbon steel, austenitized at 850°C. Continuous cooling transformation (CCT) diagrams Measure the extent of transformation as a function of time for a continuously decreasing temperature. In other words a sample is austenitised and then cooled at a predetermined rate ...

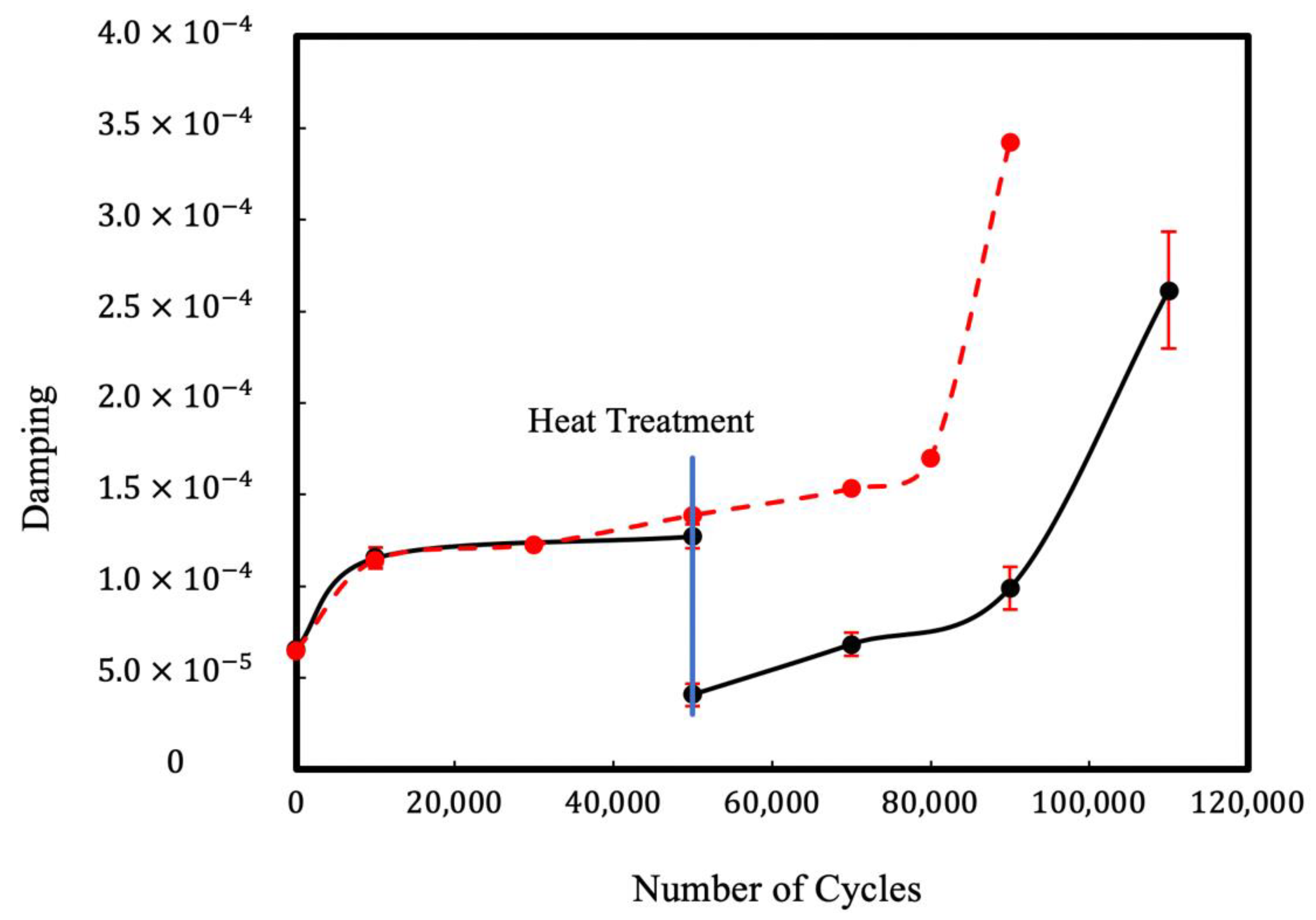

Metals Free Full Text On The Recovery And Fatigue Life Extension Of Stainless Steel 316 Metals By Means Of Recovery Heat Treatment Html

Determination of TTT diagram for eutectoid steel Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified and included M S and M F temperatures for martensite. There are number of methods used to determine TTT diagrams. These are salt bath (Figs. 1-

Ttt Diagram Tttdiagram Tricks Time Temperature Transformation Martensite Pearlite Cooling Curves Youtube

Predictive Modeling And Experimental Results For Residual Stresses In Laser Hardening Of Aisi 4140 Steel By A High Power Diode Laser Sciencedirect

0 Response to "44 ttt diagram 1018 steel"

Post a Comment